Empowering innovation through product design.

Our team's innovative approach turns concepts into visually appealing products that embody your brand's essence.

Learn More

Engineering excellence for market-ready products.

With a perfect blend of technical expertise and creative ingenuity, we partner with manufacturers to deliver products that are both reliable and ensure quality.

Learn More

Digital design services that create meaningful experiences.

We build seamless digital experiences that facilitate user conversions with our user-centric design strategies.

Learn More

Our Work

Hatch Rest 2

Industrial Design

Engineering

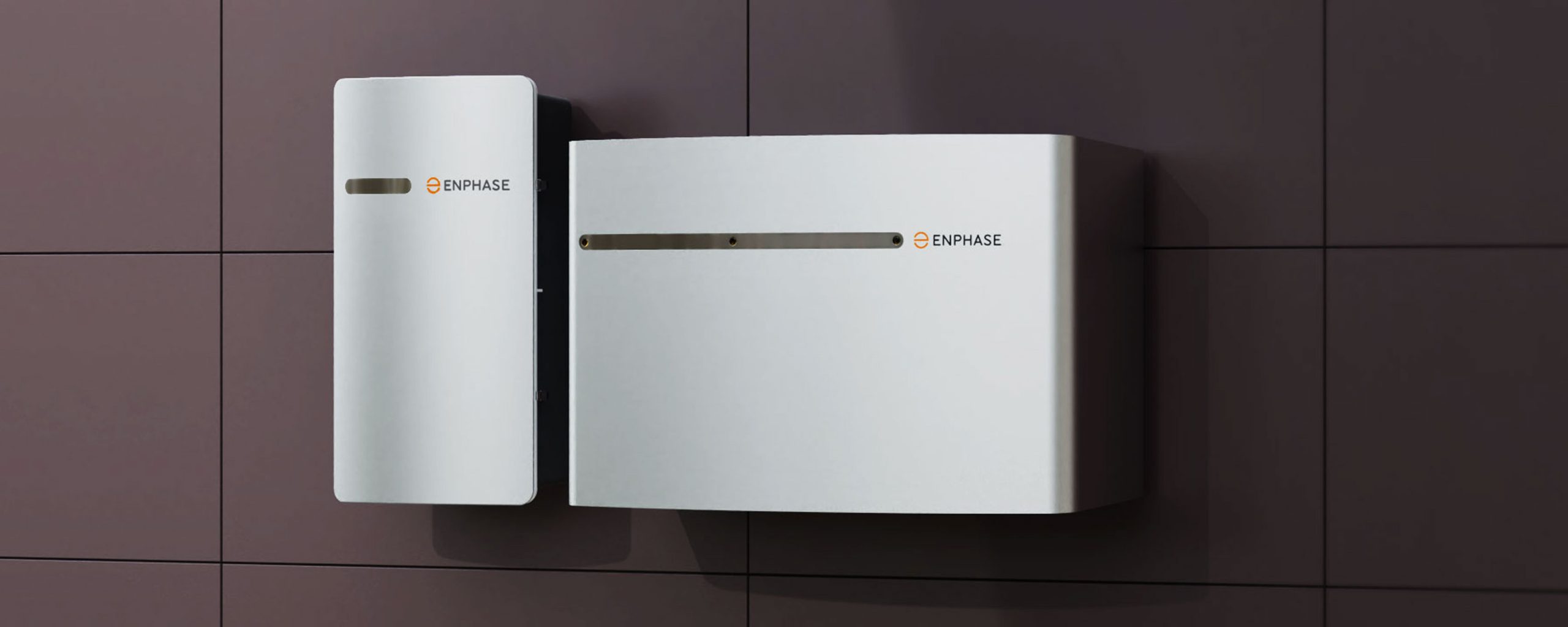

Enphase Ensemble™ System

Brand & Research

Industrial Design

She’s Birdie+

Industrial Design

Engineering

Prototyping

NPS

Brand & Research

Industrial Design

HX-S Series Keyboard

Industrial Design

Engineering

Prototyping

F2022 Warehouse Scanner

Industrial Design

Engineering

Prototyping

Product Development Services

Our product development services bring your business ideas to life, from initial concept to market-ready solutions. Leveraging innovation and strategic insight, we deliver products that meet customer needs and drive your business growth.

- Industrial Design

- Product Design

- UX & UI Design

- Mechanical Engineering

- Product Development Services

- Product Prototyping Services

Our Clients

450+ Clients have successfully launched new products to the market with us.